|

Tool & Die Components:

Work Holding Components:

Materials Handling:

Lubricators:

| |

GW

Technologies distributes the AGATHON range of precision roller guidance

components in Australasia.

AGATHON'S patented roller guides are used widely in applications calling for

high-precision tool guidance, including:

-

Press tools and the

manufacture of molds

-

Precision optics

engineering

-

Instrument

manufacture

-

Watches and

electronics manufacture

-

Photographic

components

-

Packaging manufacture

(including high-speed can making)

Agathon offers a standard

range of pillar, bush and roller configurations and can produce custom guide

sets to suit special needs.

|

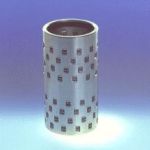

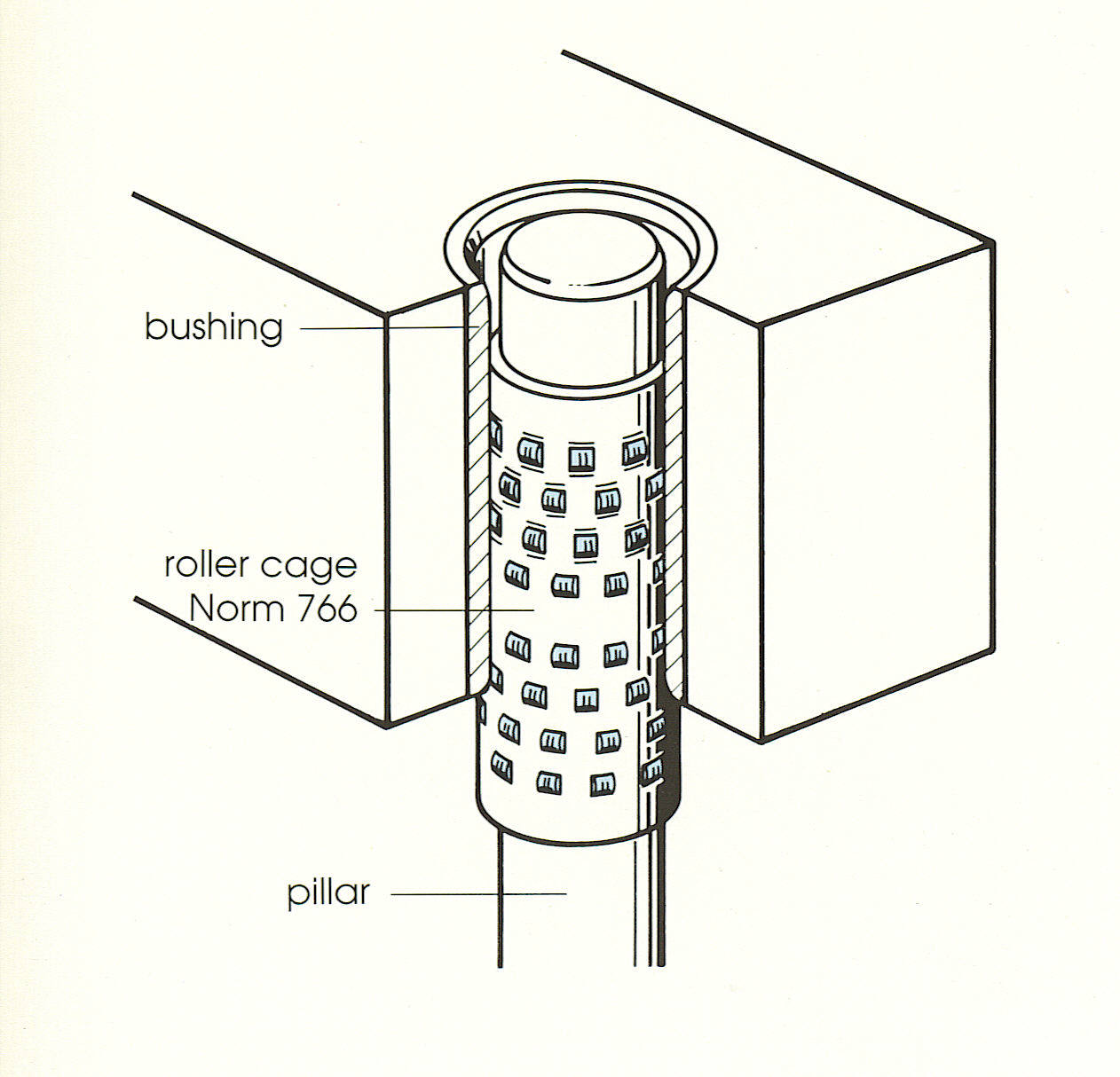

Each Agathon guide is configured as a

matched set consisting of a guide pillar, a steel bushing and a roller

cage. The roller cage is equipped with high-precision profile rollers.

Load is evenly distributed over four contact ellipses rather than the

two contact points of standard ball cages.

Because of their optimal roller

geometry, the friction value of profile rollers is markedly less than

that of standard ball cages, resulting in continuous movement of the

profile roller even at high accelerations. This ensures that heat

build-up is negligible even under the most arduous operating conditions.

The thermal stability of the profile roller system eliminates the need

for separate calculations for static and dynamic loading. |

|

All guide sets are preloaded to

micron accuracy, which guarantees movement without clearance. The

friction values of roller guides are considerably lower than those of

sliding guides - this ensures fluidity of movement and longer service

life. Service life is further enhanced by heat treatment of individual

components.

AGATHON profile rollers are capable of

carrying heavier loads than ball guides and research has shown them to

be several times more rigid, as well as significantly quieter in

operation. The design of the roller cage makes it almost impossible to

roll dirt into the pillar, reducing wear and further extending service

life. |

For enquiries, Contact GW Technologies

here.

|