|

Tool & Die Components:

Work Holding Components:

Materials Handling:

Lubricators:

| |

Ready Supersprings:

|

For applications that specifically require

conventional coil springs, GW Technologies carries stock of the full

range of "SuperSpring®"

Chrome Vanadium coil springs from Ready Technologies Inc. |

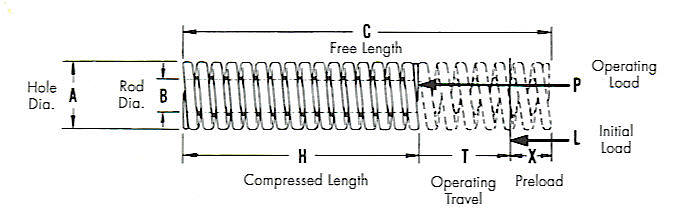

Four Load Classes, Guaranteed fit, Fully

Interchangeable

More than 400 Supersprings®

are available in four colour-coded load classifications. Lengths, diameters,

rates and colours are in accordance with ISO 10243. Guaranteed uniform lengths

and diameters provide full interchangeability between load classes. Spring

diameters are guaranteed to fit in the hole and over the rod specified in the

spring dimensional data.

Engineered for High Performance and Long Service

Life

|

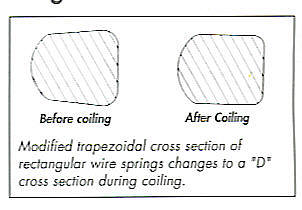

Each SuperSpring®

has the optimum design, pitch, and metallurgical content for efficient

performance. Rectangular coil springs are made from a trapezoidal cross-section

wire which changes to a "D" cross-section during coiling. This shape

results in a lower maximum stress level, substantially contributing to longer

spring life.

READY®

applies several advanced manufacturing processes to enhance the life of

SuperSprings®. These include precision

heat-treating, shot peening to reduce mechanical stresses, and presetting by

compressing to solid for increased set resistance and greatest resistance to

fatigue.

|

Dependable Performance is Quality-Assured

|

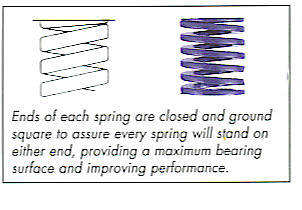

SuperSprings®

are manufactured exclusively from vacuum-degassed, valve spring quality

alloy steel. State of the art equipment, including CNC coiling and grinding is

employed to achieve consistent dimensional accuracy within narrowest tolerances.

Each production run is thoroughly inspected and documented to maintain strict

quality. The result is a die spring of unsurpassed quality which many of the

world's most demanding users specify for long, dependable performance. |

For enquiries, Contact GW Technologies

here.

|