|

Tool & Die Components:

Work Holding Components:

Materials Handling:

Lubricators:

| |

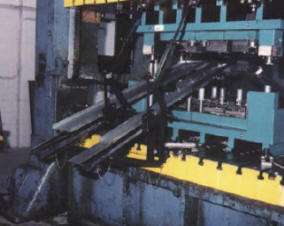

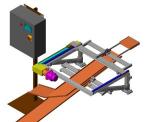

BACHHUBER AUTOMATIC PRESS

UNLOADERS

Bachhuber (BMC) press unloaders are ram-actuated press

unloaders specifically designed for parts and/or trim removal in top-unloading

press operations. Actuated by a connection to the press ram or by a servomotor,

these units significantly improve productivity and provide an efficient and safe alternative to

manual parts handling.

|

- A range of accessories is available, including

left-hand actuating arms (no additional cost), actuating arm guards, additional trays, tray out limit switches and auto-disconnect options.

- Other models available in the BMC series include

trolley-mounted models (Model 300 series) and models for heavier parts and

die cast applications.

- BMC Press unloaders connect directly to the press ram

and therefore keep up with the operating speed of the press - a press speed

of 45 SPM translates to parts unloading at a rate of 2700 parts per hour,

compared to 300-400 parts per hour for manual handling.

- BMC press unloaders replace air ejection, thereby

reducing noise levels;

- Rugged, precision-machined and welded frame for long

service life;

- Easy setup and adjustment, with 1-bolt and 1-pin

hookup and a single actuating arm.

|

|

BMC Model 75

Smallest in the BMC unloader range, designed for high-speed short-stroke presses.

Featuring:

• Up to 250mm (10") maximum stroke (tray travel)

• Up to 10" wide retrieval tray, with tray angle infinitely adjustable

from 00 to 200

• Up to 100 strokes per minute (SPM) on automatic operation

• Linear way bearings on slide for friction-free movement and accurate

travel

• Lubrication-free bearings at all other pivot points

• Adjustable height

• Press stroke range from 32mm (1.25") to 150mm (6")

• Bolster mounting (mounting brackets included)

|

|

BMC Model 100

Light weight

design excellent for quick change over and easy hookup and removal.

Featuring:

• Up to 550 mm (22") maximum stroke (tray travel)

• Up to 450mm (18") wide retrieval tray, with tray angle infinitely

adjustable from 00 to 200

• Up to 60 Strokes per minute on automatic operation

• Self-cleaning Nylon bearings on slide for friction-free movement and

accurate travel

• Lubrication-free bearings at all other pivot points

• Adjustable height

• Press Stroke range 75mm (3") to 450mm (18)"

• Bolster mounting (mounting brackets and actuating arm guard included)

|

|

BMC Model 150

-

Tray travel max. = 600.0mm [24"]

-

Press stroke range = 75.0mm to 500.0mm [3" to 20"]

-

Designed as a heavier upgrade to the Model 100, this unloader uses a

linear bearings for smoother operation.

|

|

BMC Model 200

-

Tray travel max. = 600.0mm [24"]

-

Press stroke range = 75.0mm to 500.0mm [3" to 20"]

-

Designed with two linear rails to unload wider & heavier parts and

provide greater stability.

|

|

BMC Model 316

- Tray travel max. = 850.0mm [34"]

- Press stroke range = 175.0mm to 750.0mm [7" to 30"]

- With longer mainframe and linear rails, this is

BMC's most popular

unloader.

|

|

BMC Model 320

- Tray travel max. = 1100.0mm [44"]

- Press stroke range = 300.0mm to 1000.0mm [12" to 40"]

- Designed for longer stroke

presses and to handle heavier applications.

|

|

BMC Model 614

- Tray travel max. = 1500.0mm [60"]

- Press stroke range = 250.0mm to 1000.0mm [10" to 40"]

- Model 600 series are for

those applications where large and heavy parts need unloading.

|

|

Fine Blank

Unloader BMC Model 220

The Model 220 catches the slug and pulls the finished

part off the lower die. They both land on their own trays. Parts can be

ejected onto tables, conveyors, or into containers.

|

|

Special

Custom Built Unloaders

BMC can design and build your unloader to

meet your specifications. Give us a call and see if we designed it

already, you never know...

|

For enquiries, Contact GW Technologies

here.

|