|

Tool & Die Components:

Work Holding Components:

Materials Handling:

Lubricators:

| |

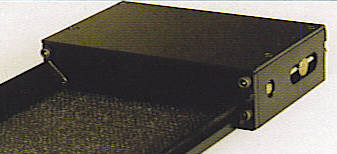

The Pax

conveyor is specifically designed for on-bolster, under-die part and

scrap removal. The "low-profile" design enables it to fit where

many conveyors will not. Designed by Pax's own tool & die craftsmen,

the conveyor is built to survive the rigours of any metal stamping

environment.

|

The drive consists of a

heavy-duty, totally enclosed fan cooled motor with a spur gear

reducer and roller chain drive. The cast aluminium end assembly is

an integral part of the chain drive housing, pulley support

and motor mount.

- Drive can be configured for

the belt to travel away from or towards motor end.

-

Conveyors are available in widths from 4 to 11 inches, in one inch

increments and 12 to 20 inches, in two inch increments.

-

Standard lengths range from 4 feet to 8 feet, in one-foot

increments, measured over the length of the exposed belt. (Conveyors longer than 8 feet or configurations other than

standard, are available as special orders.)

-

Standard left-hand-side motor

drive or optional right-hand-side motor drive available.

-

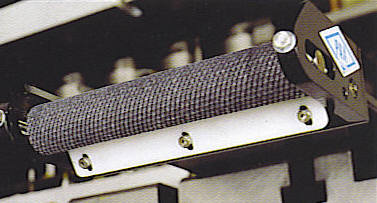

Rugged, woven polyester PVC belt

rides on a strip of high-density polyethylene to reduce wear and

friction. Belt can be changed in under 5 minutes and can be

reversed to extend service life.

|

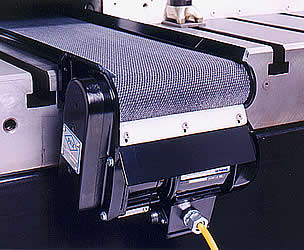

| Belt edges are

covered by flared sides of the pan, assisting with guidance of

material onto the belt and preventing scrap from working under the

belt. |

|

|

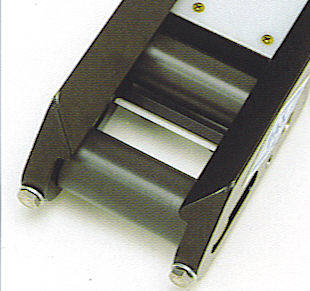

Heat-treated aluminium castings

are utilised where possible for heavy-duty, rugged support, long

life, and reduced weight. |

| Pax's low profile

design requires only 2 1/2" clearance under die.

Once installed under the die, there

is only 3/8" from the bolster to the top of the belt, allowing

plenty of clearance for parts and scrap as they drop through the die

and onto the belt.

|

|

Options:

|

Alternative Drives:

Right-angle motor drive and inverted

motor drive options are also available, in left-hand and right-hand

configurations.

R.A. and inverted drive models include

self-adjusting belt wiper.

|

|

|

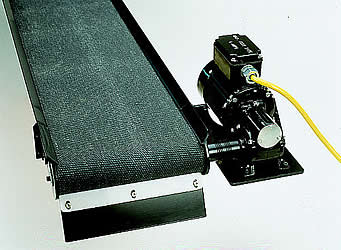

Stopped-belt sensor:

Used in conjunction with

your press control die protection circuit to stop the press if belt is

stopped. Minimises potential damage to die or conveyor resulting from

belt stoppage.

|

|

Flush-mount tension

end:

May be required in

applications where the conveyor cannot be inserted completely through

the die (requires either an inverted or right-angle drive with belt

travel toward motor, which include self-adjusting wiper). The overall

height of the flush-mount tension end is only 2".

|

|

|

Self-Adjusting wiper:

May be required in operations where there

is a possibility of small slugs adhering to the belt. The wiper greatly

reduces the chance of slugs entering between the belt and tray. The

wiper is available for fitting at the tension end and/or the drive end

of the conveyor. |

Other

options:

For enquiries, Contact GW Technologies

here.

|